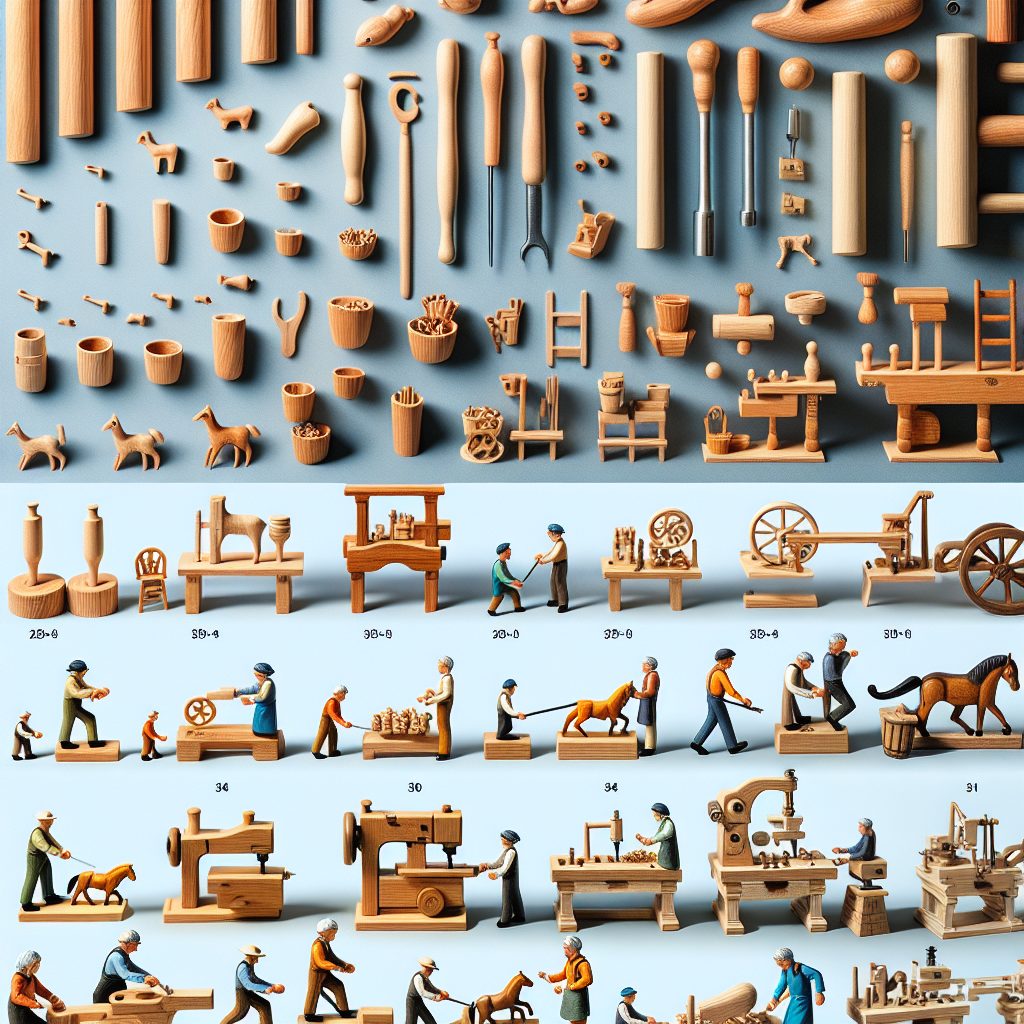

The evolution of wooden toy manufacturing techniques has been an intriguing journey, tracing back to ancient civilizations. Wooden toys, also known as traditional toys, have long been cherished for their simplicity and durability. Over the centuries, craftsmen have continuously refined and revolutionized the manufacturing process, resulting in the creation of intricate designs and innovative features.

One unique fact about wooden toys is their timeless appeal. Despite the technological advancements in the toy industry, wooden toys have managed to maintain their allure and continue captivating children and adults alike. This can be attributed to the natural appeal of wood, its warm texture and earthy scent, which evoke a sense of nostalgia and connection to nature. Additionally, wooden toys are often made using traditional methods and handcrafted with precision, adding a touch of authenticity and uniqueness to each piece.

The impact of technological advancements on wooden toy manufacturing techniques cannot be overlooked. With the advent of machinery and automation, the process of producing wooden toys has become more efficient and cost-effective. This has allowed for the mass production of wooden toys, meeting the increasing demand from consumers around the world. Moreover, the integration of modern tools and techniques has enabled artisans to push the boundaries of creativity, resulting in the development of intricate designs and captivating features.

As we delve deeper into the fascinating world of wooden toy manufacturing, there are key takeaways that deserve our attention. In the following sections, we will explore the significance of traditional craftsmanship and the role it plays in creating high-quality wooden toys. Additionally, we will discuss the impact of technological advancements on the production process, and how they have influenced the design and functionality of these cherished playthings. So, let’s embark on this enlightening journey and unravel the evolution of wooden toy manufacturing techniques.

Key Takeaways

1. Traditional wooden toy manufacturing techniques have evolved over the years to incorporate modern technology and machinery, leading to more efficient production processes.

2. Automation and the use of CNC machines have increased precision and consistency in wooden toy manufacturing, allowing for more intricate designs and intricate details to be achieved.

3. While modern techniques have improved efficiency, traditional craftsmanship is still valued in the industry, as handcrafted wooden toys continue to hold a special appeal for consumers.

4. Sustainability and eco-friendly practices are becoming increasingly important in wooden toy manufacturing, with many manufacturers opting for responsibly sourced wood and non-toxic finishes.

5. The growing popularity of wooden toys is attributed to their durability, natural appeal, and ability to stimulate creativity and imagination in children, making them a preferred choice over plastic or electronic toys.

What are the SEO optimized title question on the Evolution of Wooden Toy Manufacturing Techniques?

History of Wooden Toys

Wooden toys have been a part of human playtime for centuries. In this section, we will explore the history of wooden toys and their significance in different cultures and time periods. From ancient civilizations to modern times, wooden toys have evolved and adapted to meet the changing needs and preferences of children.

Traditional Techniques of Wooden Toy Manufacturing

The traditional techniques of wooden toy manufacturing encompass various processes and skills that have been passed down through generations. This section will delve into these techniques, such as wood selection, carving, shaping, smoothing, and finishing. These time-honored methods maintain the charm and authenticity of wooden toys, showcasing the craftsmanship involved in their creation.

Innovation in Wooden Toy Manufacturing

As the world progresses, so does the manufacturing industry, including wooden toy production. This section will explore the innovations and advancements made in the manufacturing techniques of wooden toys. It will cover topics like automation, precision tools, computer-aided design (CAD), and the impact of technology on the efficiency, quality, and safety of wooden toy production.

Sustainable Practices in Wooden Toy Manufacturing

A growing awareness and concern for the environment have led to the development of sustainable practices in various industries, including wooden toy manufacturing. In this section, we will discuss how manufacturers are incorporating eco-friendly materials, such as responsibly sourced wood and non-toxic finishes, into their production processes. We will also explore the use of renewable energy sources and waste reduction techniques in order to minimize the ecological footprint of wooden toy manufacturing.

Toy Safety Standards and Regulations

The safety of children is of utmost importance when it comes to the manufacturing of wooden toys. This section will delve into the various standards and regulations that manufacturers adhere to in order to ensure the safety and quality of their products. From material testing to age-appropriate design considerations, we will explore the measures taken to provide parents and caregivers with peace of mind.

The Future of Wooden Toy Manufacturing Techniques

As technology continues to advance and consumer demands evolve, the future of wooden toy manufacturing techniques seems promising and exciting. In this section, we will speculate on potential trends and innovations that could shape the industry. From the integration of augmented reality features to customization options, we will explore the possibilities that lie ahead for wooden toy manufacturing.

What are some tips for implementing effective wooden toy manufacturing techniques?

- Invest in modern tools and equipment to improve efficiency and precision.

- Source wood from sustainable forests to support environmental conservation.

- Stay updated with industry regulations and safety standards to ensure compliance.

- Prioritize quality control at every stage of the manufacturing process.

- Consider incorporating eco-friendly materials and finishes for a sustainable approach.

- Embrace technological advancements that can enhance design and production processes.

- Seek feedback from customers and adapt to their changing preferences and needs.

- Collaborate with other experts and professionals in the industry to exchange knowledge and ideas.

- Continuously innovate and explore new ways to make wooden toys more interactive and engaging for children.

- Regularly assess and improve manufacturing techniques to optimize productivity and profitability.

FAQ

1. What are the traditional wooden toy manufacturing techniques?

The traditional wooden toy manufacturing techniques include carving, turning, and shaping wood using hand tools such as saws, chisels, and knives.

2. How have wooden toy manufacturing techniques evolved over time?

Wooden toy manufacturing techniques have evolved with the introduction of new machinery and technology, such as CNC routers, laser cutters, and computer-aided design (CAD) software. These advancements have increased precision, efficiency, and enabled more complex designs.

3. Has the shift to modern techniques affected the quality of wooden toys?

No, the shift to modern techniques has not necessarily affected the quality of wooden toys. While traditional techniques may offer an aesthetic charm, modern techniques maintain quality through controlled precision and rigorous testing.

4. Are wooden toys made using modern techniques more expensive?

Wooden toys made using modern techniques can be priced differently depending on various factors such as design complexity, material selection, and manufacturing volume. However, advancements in automation and improved production processes have made it possible to offer a wider range of wooden toys at varying price points.

5. How do modern wooden toy manufacturing techniques prioritize safety?

Modern wooden toy manufacturing techniques prioritize safety by adhering to stringent quality control measures, ensuring the absence of hazardous materials, and complying with safety standards set by regulatory bodies. Additionally, the use of technology allows for better structural integrity and minimizing potential hazards.

6. Does the use of modern techniques result in a loss of craftsmanship?

No, the use of modern techniques does not necessarily result in a loss of craftsmanship. While some aspects of traditional craftsmanship may be automated, modern techniques still require skilled artisans to operate and oversee the machinery, ensuring attention to detail and maintaining the artistic value of wooden toys.

7. Can modern techniques offer more customization options for wooden toys?

Yes, modern techniques like CNC routers and laser cutters provide manufacturers with the ability to customize wooden toys in terms of shape, size, and intricate detailing. This allows for more personalized and unique designs to cater to customers’ preferences.

8. Are modern wooden toy manufacturing techniques environmentally friendly?

Modern wooden toy manufacturing techniques aim to be environmentally friendly by promoting sustainable sourcing of wood, minimizing waste through efficient production processes, and using non-toxic finishes. However, it is important for manufacturers to prioritize eco-conscious practices to ensure minimal impact on the environment.

9. Can traditional and modern wooden toy manufacturing techniques coexist?

Yes, traditional and modern wooden toy manufacturing techniques can coexist. Many manufacturers seamlessly blend both approaches, incorporating handcrafted details along with precision manufacturing. This allows for a balance between traditional charm and modern efficiency.

10. What does the future hold for wooden toy manufacturing techniques?

The future of wooden toy manufacturing techniques holds exciting possibilities. Advancements in technology may lead to further automation, more sustainable practices, innovative designs, and increased customization options. It is an ever-evolving industry that continues to offer timeless charm and appeal.

Final Thoughts

The evolution of wooden toy manufacturing techniques has truly revolutionized the industry. The combination of traditional craftsmanship and modern technologies has opened up endless possibilities for designers, manufacturers, and consumers alike. The ability to create intricately detailed wooden toys with precision and efficiency ensures that the charm and appeal of these timeless playthings endure.

As we move forward, it is crucial to strike a balance between innovation and upholding the values of craftsmanship. By prioritizing safety, sustainability, and customization, wooden toy manufacturing techniques can continue to capture the hearts of both children and adults, while also minimizing their impact on the environment. The future holds countless opportunities to create even more magical wooden toys that bring joy and inspire creativity in generations to come.